Test adapters

Zero-tolerance quality assurance system is the only long term solution to guarantee success in the wiring harness business.

Testing Counterparts

Our basic design principles for test fixtures:

- Counterpart does not damage the connector housing nor the contacts.

- Counterpart is designed as small as possible.

- Counterpart guides and aligns connector housing before it touches contact probes to avoid component damage.

- Counterparts with pressure test are equipped with aluminium pressure chamber to ensure long service life.

- All replaceable and adjustable parts are easily accessible for maintenance.

- All probes are easily replaced (e.g. without soldering).

- DIN916 set screws and DIN912 bolts with hex socket are used whenever possible for easy maintenance.

Counterparts Type C

- Electrically controlled pneumatic locking mechanism for housing retention

- Automatic release

- POM plastic construction for low friction insertion of housings

- High voltage versions available

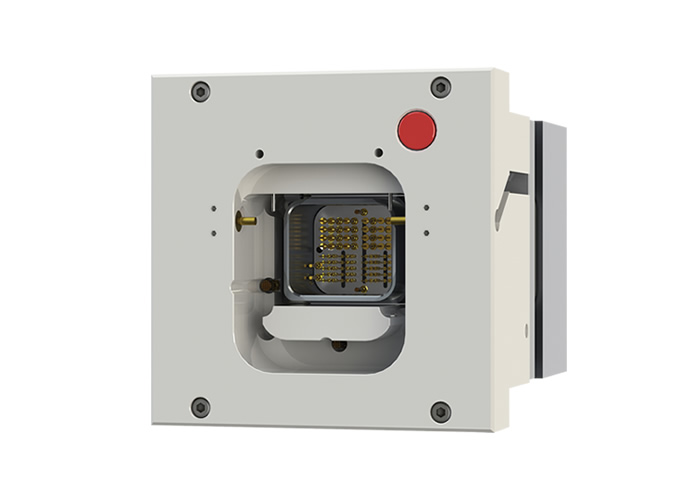

Counterparts Type D

- Zero force adapter where test probes are moved to contact position pneumatically

- Avoids component damage

- Reduces operator fatigue

Counterparts Type E

- Push-back testing of terminals using 15N position sensitive probes

- Compact design enables push-back counterparts to be as small as 50x50mm for flexible layouts

Most common detections in addition

to electrical contact test

to electrical contact test